Long range ultrasonic testing

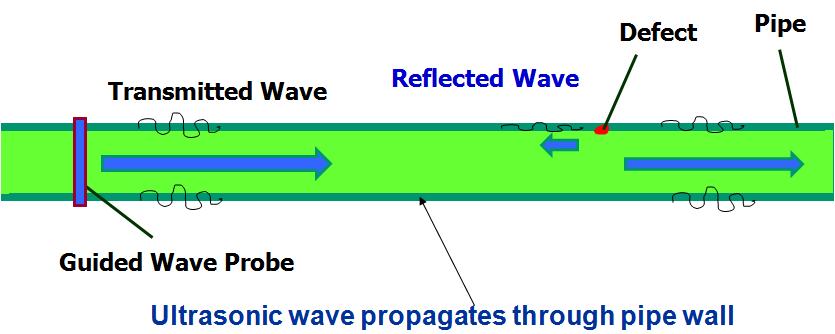

Long range ultrasonic testing is a rapid way of screening for corrosion in above ground and underground pipelines, boiler furnace tubes etc. The method enables screening of up to 100 meters of pipeline in one test, i.e. 50 meters in both directions. By fitting a ring of transducers around the pipeline, a wave maker device directs low frequency (20-100 kHz) ultrasonic waves via the transducers, longitudinally into the pipeline wall. The method effectively detects changes in the pipeline's cross-section, enabling it to indentify corrosion and other abnormalities. At the same time this provides the possibility of using welds and flanges as distance references

The test results are displayed in an easy-to-interpret visual interface on a laptop computer – enabling us to draw conclusions quickly and correctly. Upon identifying a defect we carry out follow-up detailed testing of the affected area, using complementary ultrasonic or x-ray methods.

With this highly advanced testing method you will get an accurate status report of your pipelines in the most effective way.

Benefits

- More than 100 times faster than traditional ultrasonic methods

- Up to 100 meters screening distance on pipelines above ground

- Up to 10 meters screening distance on pipelines buried in the ground

- Possibility to do sub-sea scanning

- Saves time since there is no need to remove insulation, apart from 1 meter for the transducer ring.

- Easy to screen wall penetrating pipelines (both built-in and sleeved penetrations)